Pipeline transportation

Efficient, effective and flexible tracking of your hydrocarbons from receipt to delivery

Tracking made easy

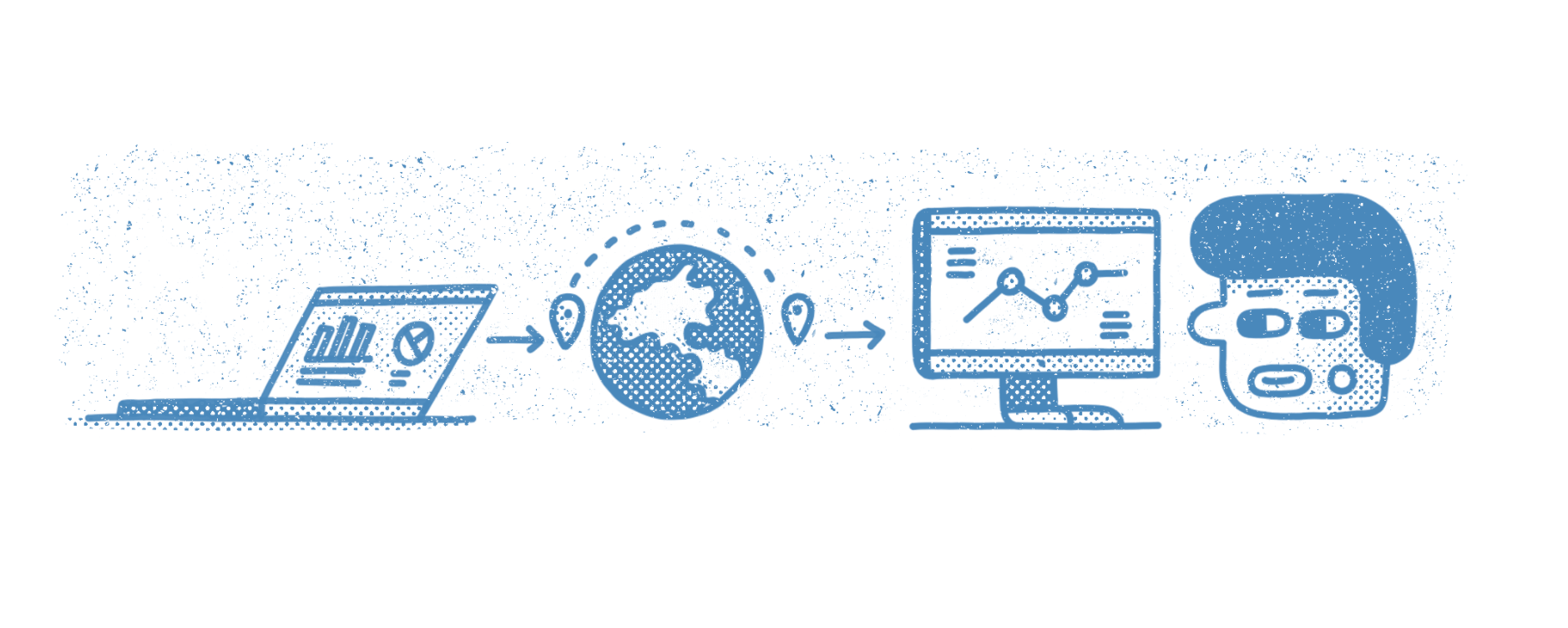

Pipeline transportation is used for oil and gas products within the upstream production asset and from the production asset to the sales point. In many cases, the pipeline system will be shared by several different producers, transporting products of dissimilar quality. It is necessary to track the movements during pipeline transportation from the receipt point into the pipeline system to the delivery point in order to reconcile the amounts received with the amounts delivered, to manage the infrastructure needed to store and transport the products, and to ensure that the owners of the product know their location. Records of operational curtailments and other events must be kept, and their impact understood and recorded. Additional complexity might be present if the pipeline system includes processing terminals which impact the amounts or quality of the products being tracked.

The network operator must be able to forecast throughput and storage requirements in order to manage current pipeline transportation operations but also to plan resource utilisation and projects into the future.

Data collection, validation and management

Operators who are transporting oil and gas products through pipelines need to track the quantity and quality of product entering and exiting the system, as well as volumes consumed or modified through processing. They also need to track inventories in storages within the transport system.

Typical data collected might include:

- Measurements; flows, pressures, temperatures

- Nominated amounts for receipt or delivery, by location

- Storage volumes or gauges

- Samples and laboratory analyses

EnergySys allows data to be entered directly into the screens, posted to the system as email attachments, retrieved from other systems automatically via Connectors, or manually uploaded from files. Files can be uploaded in Excel, CSV or text format, and you can load them in bulk by providing a zip file. The layout of these upload files is not specified by the system, and the import process can be configured to read almost any layout and import the data to the system. For automated interfaces with a SCADA system or data historian, data can be uploaded via a web services interface. Validation and verification checks can be undertaken on all raw data imported into the system.

If a mismeasurement is found the correct figures need to be recorded and, if necessary, calculations, such as allocation, re-run for the affected period.

Calculations

It is necessary to track what enters the pipeline from one or more receipt points, and what comes out at one or more delivery points. The pipeline operator needs to be able to perform calculations such as the allocation of the delivered quantities to the individual entries, and accounting for different fluid or gas qualities, if agreements so require. It may also be necessary to support other processes such as pipeline nomination, capacity and inventory management, tariffing and scheduling.

It is necessary to keep track of the accounts, that is, how much each company owns of the volumes presently in the storage and the ownership of the volumes transported.

It is important to know, at the end of the day, if any one party owes, or is owed, product. This is often referred to as an imbalance and can be calculated and addressed by the pipeline operator or carried forward into future periods.

Planning and forecasting

The annual delivery programme provides an overview of the expected transport requirements for the year ahead. In creating this plan, the Operator needs to be able to assess possible operating scenarios, with due regard to capacity and throughput limitations and planned infrastructure changes. As the year progresses, operational detail is established in the short-term forecast. Operators may need to understand the feasibility of the planned receipts and deliveries with regard to operating limits over, say, the coming 48 hours. This allows them to take mitigating actions at an earlier stage, ensuring a quality service to the pipeline stakeholders and avoiding costly last minute curtailment fees.

Commercial

How the transportation network is used by participants will be governed by commercial contracts, which can include complex arrangements for capacity rights, tariffs, penalties and application of specific pricing regimes. The product that is moved and stored in the network will be owned by more than one company, meaning that product ownership must be tracked. The terms of these agreements differ widely and are usually very specific to the asset in question.

In some pipeline systems, there might be the facility for owners, participants, and third parties, to trade capacity or product to meet long- or short-term goals. The Operator must keep track of these trades and, potentially, provide a platform on which they can be agreed.

Reporting

The data stored and generated in the application hosted on the EnergySys Cloud Platform is used for daily, monthly and annual reporting, internally and to partners and government. These reports are likely to cover:

- Commercial allocation of throughput and inventories

- Invoices and revenue

- Environmental impact

- Regulatory submissions

- General notifications relating to service outage or general operating metrics

- Performance against plan, and forecasts of future operations

Data can be exported via our web-services interface, which provides the mechanism to interface with almost any third-party system, or transmitted by email as an attachment. Attached reports can be configured to suit the layout requirements of the recipient.

Automation

Many of the activities described above – data collection and validation, calculations, report creation and distribution, for example – can be automated, freeing the team to assess performance and identify opportunities for improvement. Automation of any sequence of tasks is straightforward and can be configured by the end user to suit their specific business requirements.